TECHNOLOGY

The Benefits of Choosing Custom Caster Wheels

Caster wheels are specialized, custom-engineered wheels that meet customers’ specific requirements. This could involve creating a unique caster based on a unique design or changing an existing caster, such as changing the mounting layout, total caster height, swivel lead, and bearings.

These custom-engineered wheels and casters have many benefits, like optimizing the cost of your product, improved durability, and safety features. This blog post will explore the benefits of custom-engineered casters and their uses in various industries.

Let’s start with discussing the advantages of custom caster wheels.

Top 8 Advantages of Using Custom Engineered Wheels:

Custom-engineered wheels offer many advantages over standard off-the-shelf caster wheels. Their custom property makes them an appealing choice for businesses looking to optimize their operations. Let’s explore some of the critical benefits custom caster wheels offer.

1. Made to Match Specific Uses:

One significant advantage of custom-engineered wheels is the ability to tailor them to the unique requirements of different applications and industries. The caster industry offers flexibility to engineer and build wheels optimized for factors like load capacity, types of floors, environment, and specific equipment needs. This level of customization enables better performance and efficiency compared to generic off-the-shelf caster wheels.

2. Improved Durability and Longevity:

Custom caster wheels are constructed using high-grade materials to match the intended application. Custom-engineered wheels can handle required loads and stresses more effectively by selecting suitable materials and ensuring proper sizing and construction. This gives the casters longer lifespans, reducing maintenance and replacement costs.

3. Enhanced Safety Features:

Adding custom safety parts to casters is essential for industrial uses. Brakes, locks, guards, and other things can help reduce workplace accidents and injuries. These custom caster wheels don’t just improve safety; they’re built to align with specific industry standards and regulations, ensuring compliance and reducing liabilities.

4. Increased Maneuverability:

Maneuvering equipment easily is vital for many jobs, especially in tight spaces. Custom caster wheels and swivel offsets let workers move loads around obstacles and small spaces without trouble, making getting more things done faster and less tiring.

5. Reduced Noise and Floor Damage:

In places like hospitals, offices, and facilities, quiet operation and floor protection matter. Custom casters can have softer wheels and shock absorption to reduce noise. This prevents scuffs and scratches on floors, contributing to the space’s aesthetic appeal while making the working environment more enjoyable.

6. Compatibility with Existing Equipment:

When a company upgrades or switches out its casters, making them fit with current equipment is a big deal. Custom casters can be designed to work seamlessly with a company’s existing equipment and infrastructure, eliminating the need for costly modifications or replacements. This guarantees the best fit and functionality, reducing downtime and increasing return on investment.

7. Potential for Unique Designs:

The caster industry allows the designing of highly specialized wheels for unique uses. You can get custom wheels that fit your needs, mixing in special features, materials, and looks. This is an excellent chance for businesses to make their equipment stand out and boost their brand, giving them an edge over the competition.

8. Cost-Effectiveness:

Even though going custom with caster wheels might seem pricier at first than picking something ready-made, it tends to save money. Custom-engineered wheels offer more durability, performance efficiency, safety, and compatibility. These benefits mean lower operating and maintenance costs over time. By choosing to customize, companies can nail down the most cost-friendly option that meets their unique needs, making the most of their budget and resources.

Key Considerations When Opting for Custom Caster Wheels:

Picking custom caster wheels for a particular use requires considering some essential things to get the best durability, performance, and value.

-

Understanding Your Requirements:

The first important step is thoroughly examining your application’s unique requirements. This means looking at factors like the operating conditions, how much load the casters must handle, manoeuvrability needs, etc. Clearly defining these specifics ensures the custom engineered wheels match what you need.

-

Selecting the Right Materials:

The caster industry uses many wheel materials, each with unique properties and advantages. Polyurethane, for example, is super durable, resists chemicals and abrasion, and absorbs shocks well. Steel casters support heavier loads and hold up in harsh settings. Rubber works great on smooth surfaces, giving excellent traction and noise reduction.

-

Working with the Right Manufacturer:

Working with an established, reputable caster manufacturer such as Caster Concepts is crucial for custom-engineered wheels. Their skills and resources allow them to design casters to meet exact specifications. They also offer valuable guidance on materials, sizing, customization, etc., for optimal longevity and performance.

Use Cases of Custom Caster Wheels in Various Industries:

Custom caster wheels have applications across many industries, each with unique needs and challenges. Let’s look at how specialized engineered wheels are used in various sectors to improve productivity, safety, and efficiency.

Manufacturing & Automotive:

In manufacturing and automotive, custom caster wheels are essential for moving heavy parts, assemblies, and equipment within factories and assembly plants. These industries often need tailored casters for automated guided vehicles (AGVs) and robots to ensure smooth, precise movement of materials and finished products.

Aerospace:

The aerospace sector depends on custom caster wheels to transport large parts like engines, landing gear, and fuselages. Precision casters are essential for safely and efficiently moving sensitive equipment while maintaining cleanliness in controlled settings like clean rooms. Custom-engineered wheels enable secure handling of these critical components during manufacturing and maintenance.

Medical & Pharmaceutical:

In the medical and pharmaceutical sectors, custom caster wheels equip various gear such as hospital beds, stretchers, carts, and diagnostic devices. These sectors need casters with specific qualities like antimicrobial properties and autoclavable materials to maintain sterile conditions. Custom-engineered wheels enable smooth mobility and patient comfort and support strict hygiene standards.

Food Processing:

Food processing sites require custom caster wheels that withstand constant washdowns and resist corrosion. Stainless steel and corrosion-resistant casters are vital for maintaining cleanliness and sanitation. High-temperature casters also prove critical for equipment like ovens and cooking appliances, delivering reliable performance under extreme conditions.

Warehousing & Logistics:

In warehousing and logistics, heavy-duty custom caster wheels equip pallet jacks, order pickers, and other material-handling machinery to haul goods efficiently. Casters with tracking abilities and RFID technology can integrate to improve inventory control and streamline operations. Custom engineered wheels ensure optimal load capacity, durability, and maneuverability in these fast-settings.

Hospitality & Retail:

Hospitality and retail industries benefit from custom caster wheels that blend function and looks. Designer casters furnish furniture, display racks, and store fixtures to create visually appealing and mobile solutions. Quiet and non-marking casters are essential for customer-facing areas to reduce noise and protect flooring, ensuring a pleasant shopper experience.

Conclusion:

In summary, custom caster wheels bring many benefits to different fields by boosting how gear works, increasing safety, and making things easier to move—all while cutting costs over time. The caster industry offers customized solutions to improve their durability and life span. Choosing custom-engineered wheels means your operations run smoother, less downtime, and everyone’s safer on the job.

Businesses should consider working with a specialized manufacturer, such as Caster Concepts, to discuss their specific needs and take advantage of the benefits of custom caster wheels for their applications.

Contact their professionals to learn more about customized casters tailored to your needs.

TECHNOLOGY

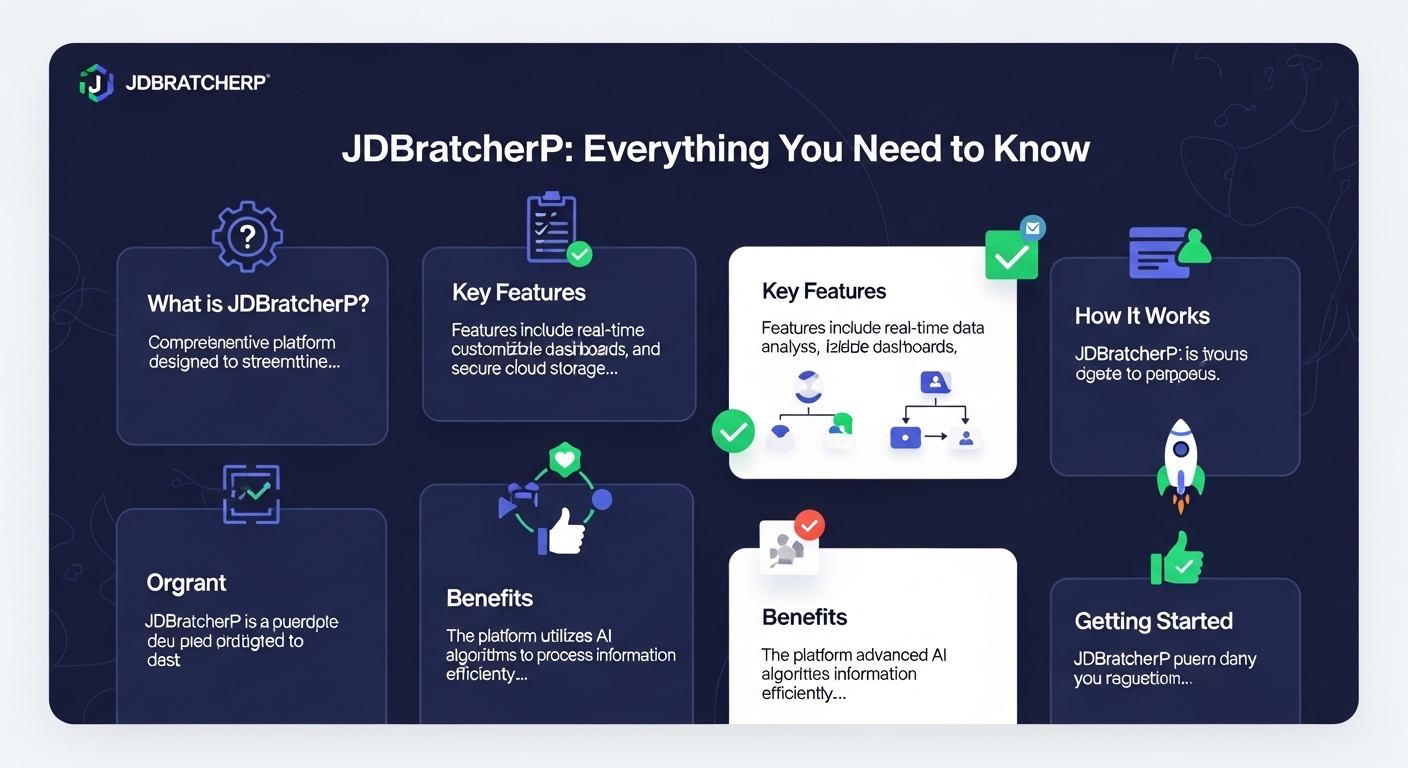

JDBratcherP: Everything You Need to Know

In today’s fast-paced digital world, businesses are constantly searching for tools that enhance productivity and streamline operations. One such solution that has been gaining attention is JDBratcherP. Designed to simplify complex processes and improve efficiency, JDBratcherP offers a range of features suitable for small businesses, large enterprises, and individual professionals alike.

This article explores JDBratcherP in detail, covering its core functionalities, benefits, and practical applications. We’ll also answer common questions to help you understand why this platform has become a preferred choice for many.

What is JDBratcherP?

JDBratcherP is an innovative software solution aimed at optimizing business processes. It integrates multiple tools into one platform, allowing users to manage projects, track tasks, analyze data, and collaborate seamlessly. Unlike traditional software that focuses on a single aspect of business management, JDBratcherP provides a holistic approach to improving productivity.

The platform is known for its user-friendly interface, advanced analytics, and robust security features, making it suitable for a wide range of industries. Whether you are in finance, healthcare, marketing, or IT, JDBratcherP can adapt to your workflow.

Key Features of JDBratcherP

1. Project Management

JDBratcherP includes an advanced project management module that helps teams plan, track, and complete projects efficiently. Features include task assignment, progress tracking, deadlines, and notifications to ensure nothing is overlooked.

2. Data Analytics

One of the standout aspects of JDBratcherP is its analytics capability. Users can generate reports, track KPIs, and visualize trends in real-time. This helps businesses make informed decisions and identify areas for improvement.

3. Collaboration Tools

Effective communication is essential for any business. JDBratcherP provides built-in collaboration tools such as chat, file sharing, and team dashboards. This ensures that all team members stay connected and informed, regardless of location.

4. Automation

JDBratcherP supports workflow automation, allowing repetitive tasks to be executed automatically. This reduces manual effort and minimizes errors, freeing up time for strategic planning.

5. Security and Compliance

Data security is a top priority. JDBratcherP employs industry-standard encryption, secure login, and compliance features to protect sensitive information and meet regulatory requirements.

Benefits of Using JDBratcherP

1. Improved Productivity

By centralizing multiple functions in a single platform, JDBratcherP eliminates the need for juggling multiple tools. Teams can work faster and more efficiently.

2. Cost Savings

Reducing the need for multiple software subscriptions lowers operational costs. JDBratcherP’s all-in-one approach provides a cost-effective solution for businesses of all sizes.

3. Better Decision-Making

With real-time analytics and reporting, JDBratcherP empowers decision-makers with actionable insights. This improves strategy formulation and enhances overall performance.

4. Scalability

JDBratcherP is scalable, meaning it grows with your business. Whether you’re a startup or a multinational corporation, the platform can handle increasing demands.

5. Enhanced Collaboration

Teams can work together seamlessly, regardless of geographic location. Collaboration tools ensure smooth communication, project updates, and file sharing in real time.

How JDBratcherP Works

JDBratcherP operates on a cloud-based model, meaning users can access it from anywhere with an internet connection. The platform typically requires users to sign up, set up their workspace, and then begin integrating existing workflows.

- Setup and Configuration: Customize JDBratcherP according to your business needs.

- Integration: Connect with other tools and software for seamless workflow.

- Task Management: Create tasks, assign them to team members, and monitor progress.

- Analytics: Generate reports and monitor key metrics.

- Automation: Automate repetitive processes for efficiency.

This simple workflow ensures that businesses can quickly implement JDBratcherP without extensive training or technical knowledge.

Use Cases of JDBratcherP

1. Small Businesses

Small businesses benefit from JDBratcherP by managing projects, tracking finances, and collaborating without investing in multiple tools.

2. Enterprises

Large corporations can use JDBratcherP to standardize operations, streamline communication between departments, and improve productivity at scale.

3. Remote Teams

For remote or hybrid teams, JDBratcherP provides a centralized hub for communication, task tracking, and file sharing, ensuring that distance doesn’t affect performance.

4. Freelancers and Professionals

Freelancers can leverage JDBratcherP to organize client projects, track deadlines, and manage billing efficiently.

Tips for Maximizing JDBratcherP

- Regular Updates: Ensure you are using the latest version to access new features.

- Team Training: Provide training sessions to familiarize your team with all functionalities.

- Automation: Identify repetitive tasks and automate them for time savings.

- Data Monitoring: Regularly review analytics to identify trends and improve strategies.

- Integration: Connect JDBratcherP with other essential software for a seamless workflow.

FAQ’s

1. What is JDBratcherP used for?

JDBratcherP is used to streamline business processes, manage projects, track tasks, and provide analytics to improve productivity.

2. Can JD BratcherP be used by small businesses?

Yes, JD BratcherP is suitable for businesses of all sizes, including startups and small teams.

3. Is JD BratcherP secure?

Absolutely. JD BratcherP employs advanced encryption and security measures to protect your data.

4. Can JD BratcherP integrate with other software?

Yes, JD BratcherP supports integrations with many popular tools to enhance workflow efficiency.

TECHNOLOGY

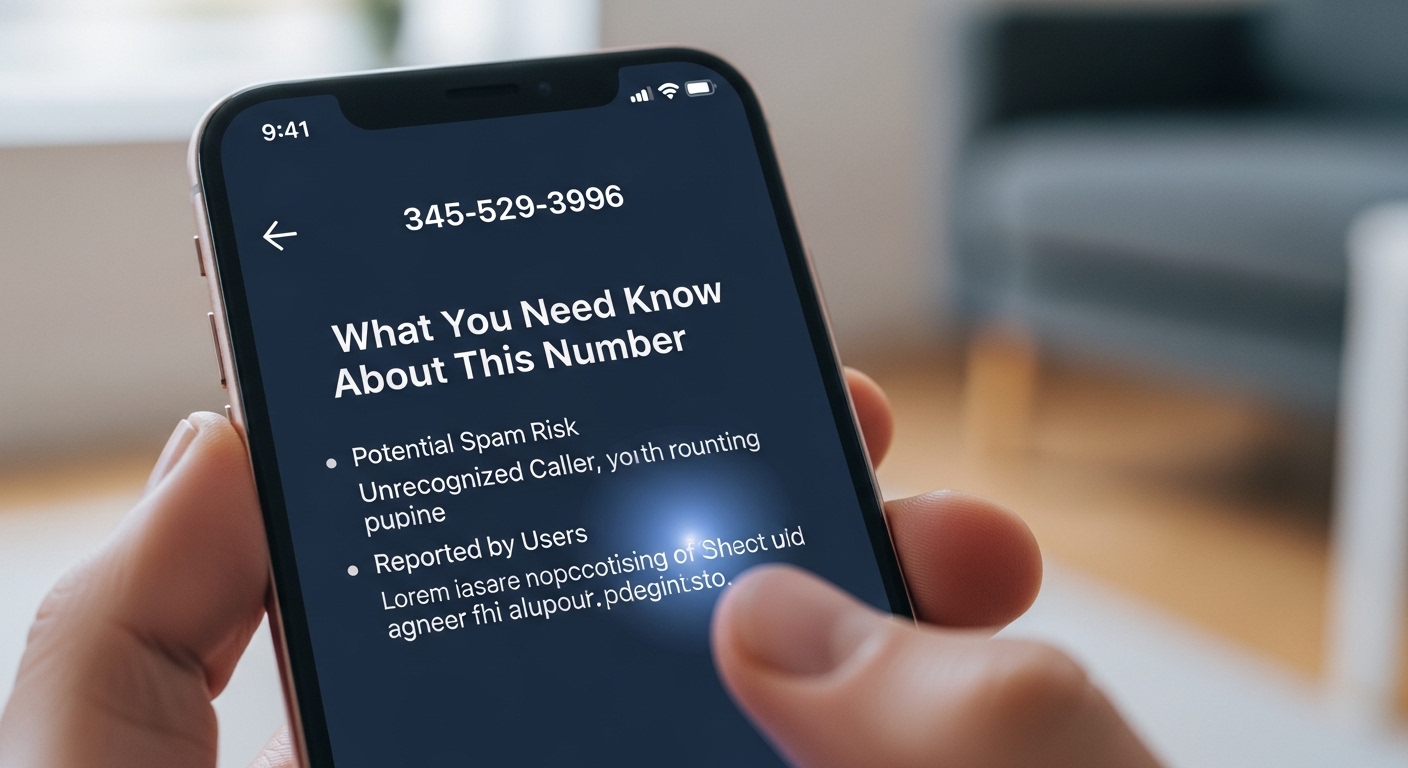

3455293996: What You Need to Know About This Number

In today’s world, receiving calls from unknown numbers is a common experience. One number that has raised concerns among many people is 3455293996. Individuals across different regions have reported receiving calls from this number, often leading to confusion and worry. This article provides a detailed, human perspective on 3455293996, including what it is, common reports, potential risks, and ways to protect yourself.

What is 3455293996?

3455293996 is a phone number that has been reported frequently by users online. Many people are unsure whether the calls they receive from this number are legitimate or if they are connected to scams. Due to the rise of telemarketing and phone-based fraud, it is crucial to understand the possible implications of calls from unfamiliar numbers like 3455293996.

Although the number may appear to originate from a valid location, it is often difficult to trace the exact source. Reports suggest that the number is sometimes used for telemarketing, scam calls, or other unsolicited activities. Understanding the origin of the number and the typical behavior associated with it can help you make informed decisions when dealing with such calls.

Scam Reports and Experiences

Multiple users have shared their experiences with 3455293996, highlighting suspicious activities linked to the number. Common reports include:

- Receiving unsolicited calls claiming there is an urgent problem with personal accounts.

- Calls offering fraudulent services or investments, often pressuring recipients to share personal information.

- Automated messages that attempt to manipulate emotions, such as claiming a financial account is compromised or that urgent action is required.

These reports indicate that many calls from 3455293996 are associated with scams. Individuals are advised to be cautious and not share any personal or financial information during such calls. While some calls may appear to come from legitimate sources, the number itself has been widely flagged as potentially suspicious.

Telemarketing and Fraud Connections

Besides scam reports, 3455293996 has been linked to telemarketing activities. Telemarketing calls are legal in many regions, but some callers may cross ethical boundaries by being overly aggressive or deceptive. Reports suggest that the number may be used to sell unnecessary services or create a false sense of urgency to pressure people into decisions they would not normally make.

The risk of fraud increases when callers use spoofing techniques to disguise their real number. Spoofing allows individuals to display a different number on caller ID, making it appear as if the call is coming from a trusted source. This makes it more challenging to identify whether a call from 3455293996 is genuine or potentially harmful.

How to Handle Calls from 3455293996

Receiving a call from 3455293996 can be unsettling, especially if you are not expecting it. Here are practical steps to handle such calls safely:

- Do not answer calls if you are unsure of the number. Let it go to voicemail if possible.

- Avoid providing personal information, banking details, or any sensitive data over the phone.

- Use phone blocking or filtering tools to prevent future calls from the same number.

- Report suspicious calls to your service provider or local authorities to help prevent potential fraud.

- Educate family members and friends about the number to prevent them from falling victim to scams.

By following these steps, you can reduce the risk associated with calls from 3455293996 and protect your personal information.

Tips to Avoid Scams

While 3455293996 is just one of many numbers linked to scam activities, adopting safe phone practices is essential. Here are additional tips to stay protected:

- Verify any unexpected calls through official channels before taking action.

- Be cautious of callers who insist on immediate payments or demand secrecy.

- Do not click on links or download files sent by unknown callers.

- Register your number on official do-not-call lists to reduce telemarketing calls.

- Regularly check for updates from consumer protection agencies regarding new scam numbers.

Being proactive and cautious is the most effective way to prevent fraud and maintain peace of mind when dealing with unknown numbers like 3455293996.

Conclusion

3455293996 is a number that has generated concern due to frequent reports of unsolicited calls, telemarketing activities, and potential scams. While not every call from this number may be harmful, it is important to exercise caution. Understanding the nature of such numbers and taking preventive measures can protect your personal information and reduce stress from unexpected calls.

Staying informed and aware of phone-based threats ensures that you can respond safely and make decisions that protect your privacy. By following the guidelines outlined in this article, you can handle calls from 3455293996 confidently and responsibly.

Frequently Asked Questions (FAQ’s)

1. Is 3455293996 a scam number?

Many reports indicate that the number has been linked to scams, though not every call may be harmful. Caution is advised.

2. Should I answer calls from 3455293996?

It is safer to avoid answering calls from this number unless you are expecting it or can verify the caller’s identity.

3. How can I block 3455293996?

Most smartphones allow you to block specific numbers. Use the built-in call blocking feature or a call-filtering app.

4. Can the number be traced?

The number may be spoofed, making it difficult to trace. It is best to focus on safety rather than identification.

TECHNOLOGY

Alamedamp: Features, Uses, and Benefits

Alamedamp is an innovative solution designed to enhance comfort, safety, and efficiency across a variety of environments. Whether in industrial settings, residential construction, or specialized engineering applications, Alamedamp provides reliable performance and long-lasting benefits. This article explores the key features, common uses, and advantages of Alamedamp to help you understand why it is becoming a preferred choice among professionals and DIY enthusiasts alike.

What Is Alamedamp?

Alamedamp refers to a line of damping materials and products engineered to reduce vibrations, noise, and structural resonance. These products are used to improve acoustic performance, reduce mechanical wear, and enhance overall stability in structures and machines.

The core principle of Alamedamp technology is to absorb and dissipate vibrational energy, preventing it from transferring through surfaces and components. This makes it ideal for situations where vibration control, sound management, and structural integrity are critical.

Key Features of Alamedamp

High-Performance Vibration Damping

Alamedamp products are specifically formulated to provide exceptional vibration absorption. They are effective in contexts where machines operate at varying frequencies, reducing:

-

Mechanical hum

-

Resonance in structural elements

-

Wear and tear on moving parts

This helps extend the lifespan of machinery and improves operational stability.

Superior Noise Reduction

Noise pollution can negatively impact comfort, safety, and productivity. Alamedamp materials help reduce sound transmission by blocking and absorbing sound waves. This makes them especially useful in environments where quieter operation is necessary, such as:

-

Residential buildings

-

Recording studios

-

Offices and commercial spaces

Durable and Long Lasting

Alamedamp is engineered for durability and resilience. Its materials are designed to withstand:

-

Extreme temperatures

-

Humidity and moisture

-

Long-term mechanical stress

The robust nature ensures consistent performance even in challenging environments.

Easy Installation

Many Alamedamp solutions are designed with user convenience in mind. They can be:

-

Cut to size

-

Applied with adhesives

-

Integrated into existing infrastructure without complex tools

This ease of use saves time and reduces installation costs.

Versatile Material Options

Alamedamp comes in various forms, such as sheets, strips, and molded components. Different formulations are available to meet specific project requirements, offering designers and engineers flexibility in application.

Common Uses of Alamedamp

Industrial Machinery

In manufacturing plants and production facilities, vibration control is vital to maintaining precision and preventing premature equipment failure. Alamedamp products can be applied to:

-

Conveyor systems

-

Heavy-duty motors

-

Compressors and pumps

Reducing vibration improves accuracy and enhances safety for workers.

Automotive Applications

Vehicles experience constant vibration from engines, road surfaces, and mechanical components. Alamedamp helps:

-

Reduce engine noise

-

Minimize structural vibration

-

Improve passenger comfort

It is used in areas such as engine bays, dashboards, and undercarriage components.

Building and Construction

In both residential and commercial construction, controlling noise and vibration enhances occupant comfort. Alamedamp materials are used in:

-

Flooring systems

-

Walls and partitions

-

HVAC equipment mounts

These applications help create quieter, more resilient structures.

Consumer Electronics

Small devices like printers, computers, and audio equipment also benefit from vibration damping. Alamedamp components can improve:

-

Audio clarity

-

Component longevity

-

Overall user experience

In high-end audio systems, damping materials minimize unwanted resonance that can distort sound.

Marine and Aerospace

In specialized industries such as marine engineering and aerospace, vibration and noise control are paramount. Alamedamp is selected for applications where weight, performance, and reliability are tightly balanced.

Benefits of Using Alamedamp

Enhanced Comfort and Safety

By reducing noise and vibration, Alamedamp contributes to safer and more comfortable environments. This is particularly important in:

-

Workplaces

-

Public buildings

-

Residential spaces

Improved Equipment Lifespan

Excessive vibration accelerates wear on mechanical parts. Alamedamp reduces this strain, prolonging equipment life and decreasing maintenance costs.

Cost Savings

Though the upfront investment in damping materials may seem significant, long-term savings emerge from:

-

Lower repair and replacement costs

-

Reduced energy waste

-

Enhanced operational efficiency

Better Acoustic Performance

Alamedamp helps create acoustically optimized environments, which is crucial for:

-

Recording studios

-

Theaters

-

Conference rooms

Clearer sound and reduced echo improve the functionality of these spaces.

Increased Structural Integrity

In construction and engineering, controlling resonance improves the stability and resilience of structures. Alamedamp contributes to this by minimizing stress points that can lead to material fatigue.

Choosing the Right Alamedamp Product

When selecting an Alamedamp solution, consider the following factors:

-

Application environment: Indoor or outdoor use can affect material choice

-

Frequency range: Match the damping material’s capabilities with expected vibration frequencies

-

Temperature tolerance: Ensure materials can withstand operational conditions

-

Ease of installation: Choose forms that fit your project’s complexity and timeline

Consulting with technical specialists or manufacturers can help you identify the optimal product for your specific needs.

Installation Tips for Best Results

-

Prepare Surfaces: Clean and dry surfaces before application

-

Measure Carefully: Cut materials to fit precisely for maximum effectiveness

-

Follow Guidelines: Use manufacturer recommendations for adhesives and mounting

-

Test and Adjust: After installation, evaluate performance and make adjustments if necessary

Proper installation ensures you gain the full benefit from Alamedamp products.

Comparing Alamedamp With Alternatives

While many vibration damping products exist, Alamedamp stands out due to:

-

Wide range of applications

-

High durability

-

Ease of use

-

Proven performance history

Alternative solutions may require more complex installation or offer limited frequency control.

Common Misconceptions

Some users assume that all damping materials perform equally. In reality, effectiveness depends on:

-

Material composition

-

Thickness

-

Frequency response

Choosing a generic product without technical evaluation can lead to suboptimal results.

Future Trends in Damping Technology

As industries evolve, vibration and noise control solutions like Alamedamp continue to advance. Innovations focus on:

-

Lightweight composite materials

-

Smarter integration with digital sensors

-

Customizable performance profiles

These trends promise even better performance in the coming years.

Conclusion

Alamedamp offers reliable, effective solutions for vibration and noise control across multiple industries. Its high-performance damping features, versatility, and long-term benefits make it a practical choice for engineers, designers, and builders.

-

HEALTH2 years ago

HEALTH2 years agoIntegrating Semaglutide into Your Weight Loss Plan: A Practical Guide

-

HOME IMPROVEMENT2 years ago

HOME IMPROVEMENT2 years agoHow to Choose the Perfect Neutral Area Rug for Every Room

-

FASHION2 years ago

FASHION2 years ago7 Celebrity-Inspired Elegant Summer Dresses For 2024

-

LAW2 years ago

LAW2 years agoTeenage Drivers and Car Accidents in California: Risks and Parental Liability

-

CONSTRUCTION2 years ago

CONSTRUCTION2 years agoConstruction Site Safety Regulations in New York and Your Rights as a Worker

-

LAW2 years ago

LAW2 years agoPost-Divorce Considerations in California: Modifications and Long-Term Planning

-

HOME2 years ago

HOME2 years agoSandra Orlow: The Teen Model Who Captivated the Internet

-

FINANCE2 years ago

FINANCE2 years agoDigital Asset Management in Florida Estate Planning